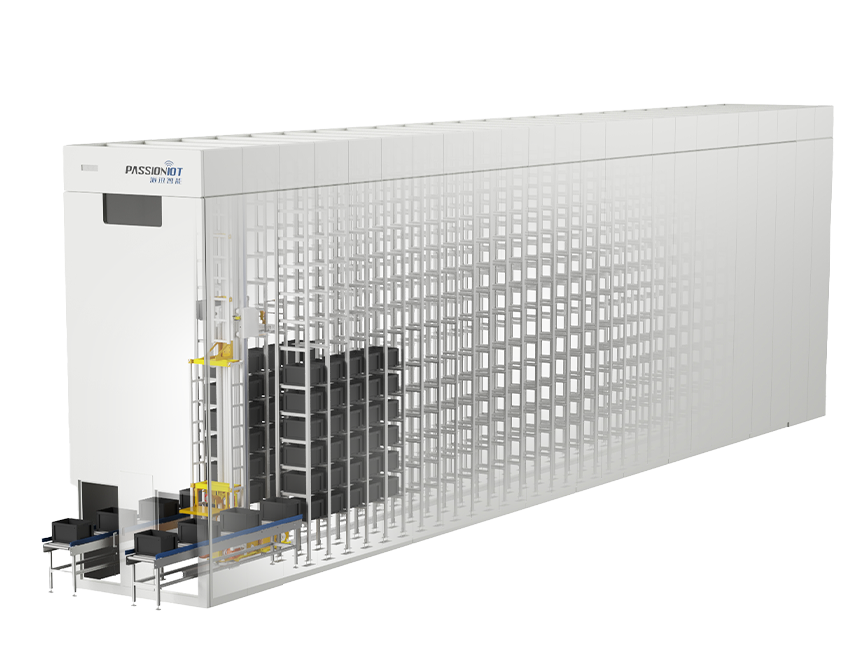

The demand for more intelligent logistics is rising in tandem with industry demands for increased efficiency. When combined with small technologies such as the PassionIOT Miniload System, the as/rs automated storage and retrieval system provides a systematic answer to warehouse limitations. Totes and boxes, among other load carriers, can be supported by this state-of-the-art system that maximizes the utilization of horizontal and vertical space. No matter how densely packed your goods are, its automatic stacker cranes will get the job done accurately.

Efficient Warehousing with PassionIOT’s Miniload System

PassionIOT’s Miniload System integrates seamlessly into dynamic environments, optimizing operational workflows without requiring extensive floor space. As more companies shift towards leaner operations, an as rs warehouse equipped with this technology becomes increasingly viable for handling small and medium-sized items with high turnover.

Enhancing Throughput with Automation

The as/rs automated storage and retrieval system plays a pivotal role in improving access times and throughput. Especially in fast-paced industries, minimizing manual labor while maintaining precision is essential. PassionIOT’s emphasis on automated handling ensures not just efficiency, but also consistency in high-volume tasks. The automation embedded in the as rs warehouse structure facilitates scalable performance as business needs evolve.

Conclusion

Rather than chasing slogans, forward-looking companies are embracing technologies that quietly reshape their logistics backbone. The as/rs automated storage and retrieval system, especially within an as rs warehouse powered by PassionIOT’s Miniload System, is not about bold promises—it’s about measurable transformation. In today’s warehouses, precision is currency, and integration is strategy.