Through the use of specialist inspection equipment, Juxin (Anhui Juxin Intelligent Manufacturing equipment Co., Ltd.) satisfies the requirements of manufacturing for dimensional precision. In order to ensure that tight production standards are upheld in the wire and cable manufacturing industry, it has become necessary to utilize innovative wire testing equipment. Manufacturers are given the capacity to identify extremely small deviations that have the potential to impact compliance and product performance through the use of this technology, particularly the cable wire tester devices that have been created for the detection of particles and size.

Non-Contact Measurement Technology

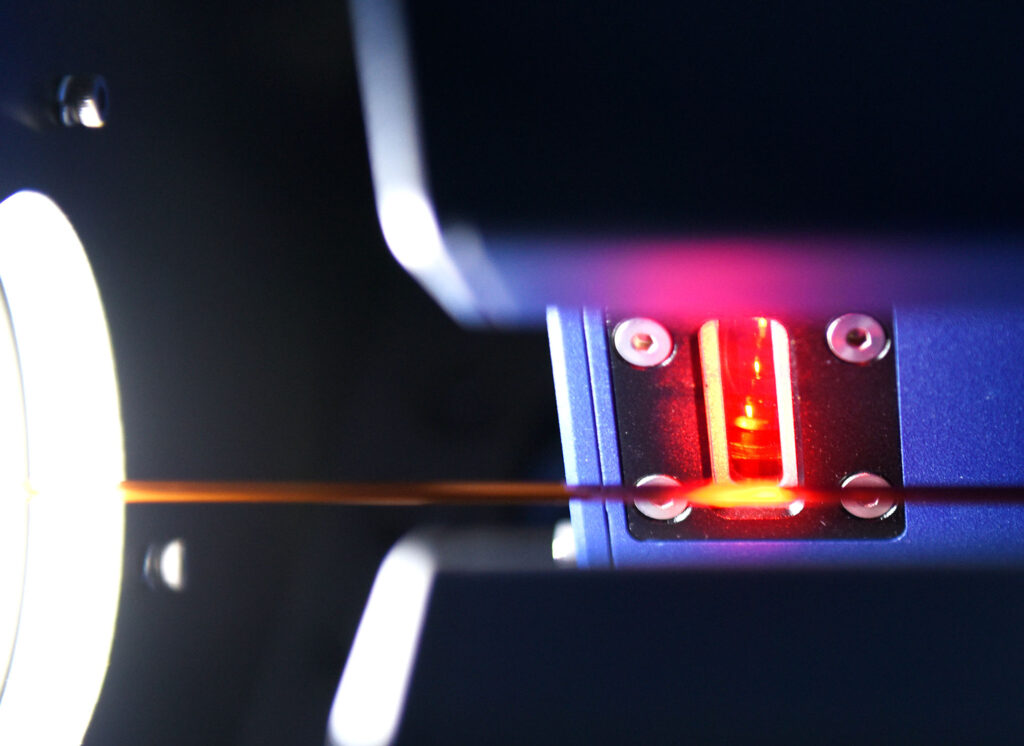

A significant advantage of modern wire testing equipment is its ability to inspect without physical contact. The particle and size detector utilizes high-precision optical sensors or laser measurement technology to perform real-time inspection of moving materials. This non-contact approach prevents material contamination or damage during the inspection process, ensuring that the cable wire tester does not itself become a source of quality issues while verifying product dimensions and surface conditions.

Intelligent Data Analysis Capabilities

Beyond simple measurement, this wire testing equipment provides valuable analytical functions. The system incorporates smart analytics through built-in automated test systems that offer data visualization and trend analysis. This cable wire tester can also support closed-loop process control, enabling real-time adjustments to production parameters based on measurement results. This capability transforms quality control from a passive inspection activity to an active process management tool.

Adaptable Configuration for Diverse Applications

The versatility of inspection systems is crucial for manufacturers with diverse product lines. This wire testing equipment is designed with adaptability in mind, capable of accommodating a wide range of materials and profile types. The cable wire tester can be configured for both standard and custom profiles, making it suitable for various production environments without requiring significant reconfiguration between different product runs or material types.

In the end, assurance of quality in modern wire manufacturing relies heavily on the incorporation of precision measurement wire testing equipment. All-inclusive solutions for dimensional verification and surface quality control are offered by Juxin’s cable wire tester systems, which feature cognitive analytics, non-contact inspection capabilities, and flexible configuration options. This technology supports quality control and process optimization goals by ensuring that wire and cable products meet exact dimensions specifications through efficient, accurate, and adaptive inspection processes.