High-capacity data transmission requires a sophisticated ecosystem of hardware and software to ensure that every photon carries its intended information without distortion. A modern measurement system serves as the diagnostic foundation for this process, providing the tools necessary to characterize the physical layer of fiber networks. Central to this architecture is the optical intensity modulator, a device that converts electrical data into light pulses with extreme precision. As bandwidth requirements escalate toward the terabit scale, the complexity of maintaining signal fidelity increases. Consequently, enterprises are prioritizing integrated solutions that offer high reliability and automated calibration to ensure that high-speed links remain robust under varying environmental conditions.

Core Components of a Reliable Optical Intensity Modulator

The effectiveness of an optical intensity modulator depends on its ability to maintain a consistent extinction ratio and low insertion loss across a wide frequency range. In high-frequency applications, such as 67GHz or 110GHz systems, even minor phase shifts can lead to significant data errors. To prevent this, specialized thin-film lithium niobate (TFLN) technology is utilized to provide the necessary bandwidth and thermal stability.

The Necessity of Automated Bias Control

Precision in modulation is impossible without a dedicated intensity modulator bias controller to manage the operating point of the device. Because material properties can shift due to temperature changes or aging, automated bias control for intensity modulators is required to provide real-time adjustments. This feedback mechanism ensures long-term stability, preventing the “drift” that often compromises signal quality in uncooled environments.

Deployment in Advanced Fiber Optic Test Equipment

To achieve rigorous quality standards, the information and communications sector relies on specialized fiber optic test equipment that can simulate real-world stress. These testing platforms utilize high-performance modulators and controllers to verify the threshold and linearity of optical transceivers. By incorporating an optical intensity modulator with automated bias stabilization, the test equipment can deliver repeatable results across thousands of cycles. This level of automation is essential for B2B production lines, where the speed of verification directly impacts the time-to-market for 800G and 1.6T optical modules.

Conclusion

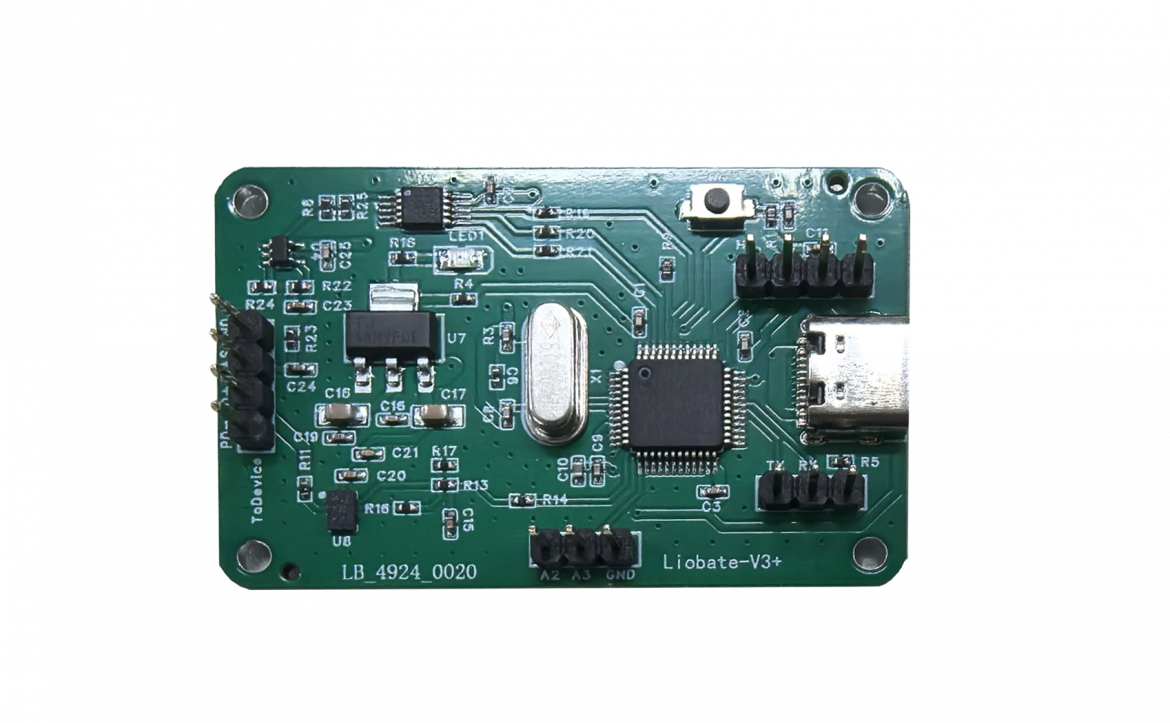

The evolution of digital infrastructure is inextricably linked to the precision of its underlying measurement and modulation hardware. Through the successful integration of high-speed TFLN chips and automated control systems, the industry can meet the growing demand for sustainable, high-capacity connectivity. High-tech enterprises like Liobate are central to this progress, providing the specialized TFLN modulator chips and fiber optic test equipment needed to drive next-generation networks.