The journey from a digital blueprint to a high-performance physical part is fraught with technical hurdles. For industries like aerospace, medical devices, and semiconductors, the difference between a successful product and a costly failure often lies in a few microns. While CAD software can simulate a design’s function, it cannot always account for the physical realities of material stress, tool wear, or surface finish requirements. This critical junction is where precision manufacturing exhibitions play a vital role, offering a hands-on environment to validate and optimize the production process.

As a primary hub for industrial innovation in South China, ITES China has become the go-to destination for engineers and procurement managers seeking to close the gap between conceptual design and high-volume manufacturing. By showcasing the entire value chain in a single venue, the event transforms theoretical possibilities into viable industrial solutions.

Visualizing the Workflow: From Concept to Component

A standout feature of a specialized contract manufacturing exhibition is its ability to map out the “Design for Manufacturability” (DFM) process. Attendees do not just see finished parts; they see the specific sequence of operations required to create them. For instance, at ITES China, visitors can follow a part’s trajectory from raw material selection through complex 5-axis milling to final precision inspection.

This transparency is essential for high-stakes sectors. When an engineer can physically inspect a micro-hole drilled in a hard, brittle material or a complex cavity milled into a titanium alloy, they gain immediate feedback on their design’s feasibility. The exhibition floor acts as a live troubleshooting session, where exhibitors from the Precision Component Design & Manufacturing hall offer expertise on reducing part count, optimizing tool paths, and selecting cost-effective surface treatments.

Technology Integration: Hardware Meets Intelligence

Modern precision manufacturing exhibitions have moved beyond simple tool displays to highlight “Embodied Intelligence.” In 2026, the integration of AI-driven control systems and automated metrology is the central theme. At ITES China, this is evidenced by the seamless workflow between machining centers and inspection instruments.

Instead of treating quality control as a post-production hurdle, the expo demonstrates in-process probing and optical measurement systems that provide real-time data feedback. This allows for closed-loop manufacturing where the machine can self-correct for thermal expansion or tool deflection, ensuring that the design intent is flawlessly executed without manual intervention. Seeing these systems interact—often involving collaborative robots (cobots) for part handling—helps businesses understand the ROI of upgrading from a single-machine shop to a fully integrated production cell.

Strategic Sourcing for Regulated Industries

For those in the medical or semiconductor equipment sectors, sourcing is about more than just finding a machine; it is about finding a certified partner. A professional contract manufacturing exhibition provides a pre-vetted pool of suppliers who understand the rigorous standards of ISO and cleanroom production.

ITES China facilitates this through specialized zones tailored to these high-growth industries:

- Medical Device Supply Chain: Focused on biocompatible materials and micron-level precision for implants and surgical tools.

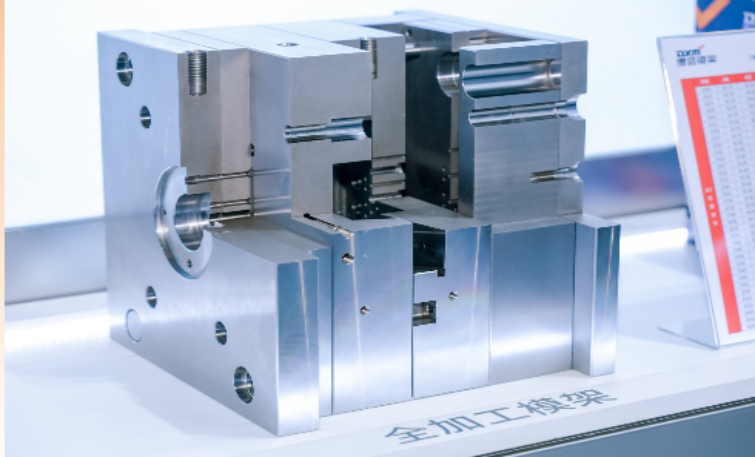

- Precision Parts & Molds: Highlighting specialists in ultra-precision stamping and non-traditional processes like EDM.

- Advanced Tooling & Consumables: Showcasing the specialized cutters and coatings necessary for high-speed machining of exotic alloys.

Forging the Future of Industrial Efficiency

The value of attending a premier precision manufacturing exhibition lies in its ability to condense months of research and supplier audits into a single, high-intensity visit. By engaging directly with technical experts and witnessing equipment in a live environment, decision-makers can bypass the “trial and error” phase of new product introduction.

Platforms like ITES China ensure that as designs become more complex, the manufacturing ecosystem is ready to meet those demands. Whether you are looking to optimize a single workflow or redesign an entire supply chain, the connections made on the exhibition floor are the building blocks of a more efficient, precise, and competitive manufacturing future.