Utilizing lithium battery automation equipment effectively is essential for modern battery manufacturing. This technology streamlines processes, enhances precision, and significantly increases production efficiency. Among the various types of automation equipment, coating machines and custom battery production lines stand out as critical components in delivering high-quality lithium batteries.

Understanding the Coating Machine

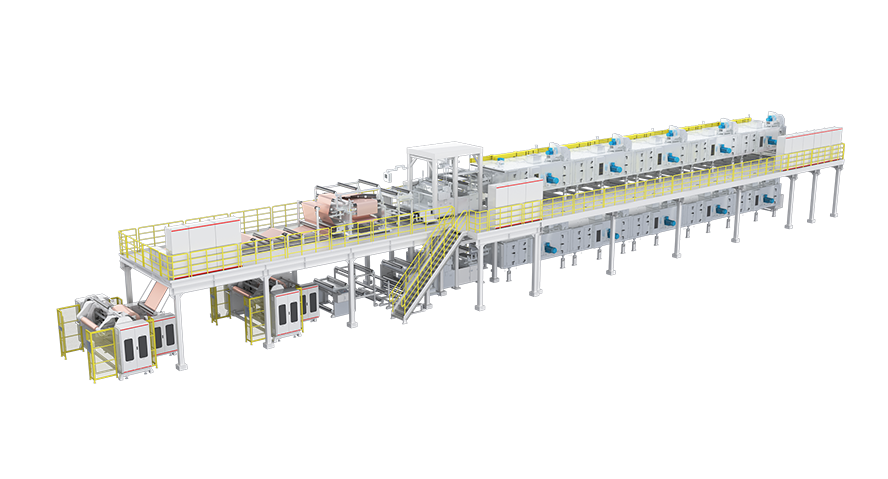

A coating machine plays a pivotal role in the lithium battery manufacturing process, particularly during the electrode preparation stage. The Double-Layer Super-E Coating Machine, such as the advanced 1800 Series, features a roller width of 1800 mm and a maximum coating width of 1550 mm. This machine applies a uniform coating of active materials on substrates, ensuring optimal adhesion and performance. Proper operation of this equipment involves adjusting parameters, such as coating thickness and speed, to meet specific product requirements.

Integrating with a Custom Battery Production Line

Integrating a coating machine into a custom battery production line is crucial for optimizing overall production efficiency. A well-designed production line will incorporate various automated processes, including material handling, mixing, and assembly stages. Each component must work seamlessly with the coating machine to ensure a smooth flow of production. This integration allows manufacturers to tailor their operations to specific product needs while maximizing throughput and minimizing waste.

Training and Maintenance Best Practices

Effectively using lithium battery automation equipment, including coating machines, requires proper training and routine maintenance. Operators should receive comprehensive training on machine setup, operation, and troubleshooting procedures. Regular maintenance ensures that equipment remains in peak condition, reducing downtime and enhancing productivity. Establishing a preventive maintenance schedule for the coating machine and other production line components is vital for long-term operational success.

Embracing Innovation with Yinghe

Utilizing lithium battery automation equipment, like the Double-Layer Super-E Coating Machine, is essential for achieving high efficiency in battery manufacturing. Companies looking to optimize their custom battery production lines should consider partnering with experts in the field. Yinghe specializes in providing state-of-the-art automation equipment for lithium battery production. By leveraging Yinghe‘s advanced technologies, manufacturers can enhance their production capabilities and stay competitive in the fast-evolving battery industry.