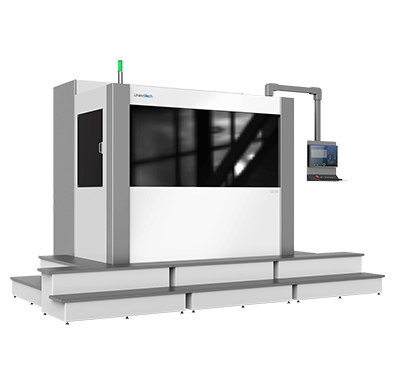

Industrial 3D printers are revolutionizing manufacturing processes across various industries by providing advanced capabilities, including the ability to print using a wide variety of materials. Among these, the industrial resin 3D printer stands out due to its versatility and precision. One company that has mastered this technology is UnionTech, an industrial 3D printer manufacturer known for its large industrial 3D printer solutions. Their flagship model, the RSPro2100, exemplifies the cutting-edge potential of SLA printing, particularly in the realm of diverse material applications.

Precision and Versatility in Material Selection

An industrial resin 3D printer like the RSPro2100 is designed to handle an array of materials, each with unique mechanical and aesthetic properties. This adaptability is essential for industries that require customized prototypes or production parts. By utilizing different resins, manufacturers can produce components with varying degrees of flexibility, strength, and surface finish. The ability to use a wide range of materials makes these printers indispensable for fields like aerospace, automotive, and medical device production.

Optimizing Efficiency in Mass Production

When dealing with large industrial 3D printers, efficiency is a key factor. The RSPro2100’s three-laser scanning system enhances printing speed, reducing the time it takes to produce complex parts. This system is particularly beneficial for mass production, where the need for rapid, high-quality output is crucial. The large format of the RSPro2100 allows businesses to print bigger parts in a single process, cutting down on production costs and time while maintaining exceptional detail and finish.

Enhancing the Industrial Manufacturing Workflow

Incorporating an industrial resin 3D printer into a manufacturing workflow brings multiple benefits, especially when scaling up production. These printers not only increase the range of materials that can be used but also improve the precision and consistency of the parts. The fine surface finish and high level of detail achievable with the UnionTech RSPro2100 ensure that parts meet stringent industry standards. Moreover, the printer’s adaptability to various resin types allows companies to switch between different production needs without investing in new equipment.

Conclusion

The flexibility and precision of an industrial resin 3D printer like the RSPro2100 offer unparalleled advantages for large-scale industrial applications. UnionTech, as an experienced industrial 3D printer manufacturer, provides a solution that supports diverse material printing, making it an essential tool for businesses in sectors that demand high-quality, customized parts. From prototypes to mass production, the RSPro2100 is a key enabler of innovation in manufacturing.